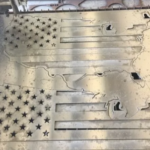

CNC Water Jet Cutting

Abrasive water jet cutting can virtually cut any material quickly and efficiently. Made in the USA, our OMAX Maxiem 1530 is equipped with state-of-the-art CNC software and technology to have the fastest cutting speeds and best precision compared to any competitive abrasive water jet in the industry by utilizing 50,000 PSI (Pounds Per Square Inch) of water mixed with premium garnet. With the expertise of our highly skilled fabricators/machine operators, we are able to maintain tolerances of +/- 0.0075” and provide exceptional edge quality. A critical advantage to water jet cutting is that it does not create any heat-affected zones or mechanical stresses to your product. Our OMAX Water Jet allows us up to a 5’ x 10’ cutting envelope to accept those larger projects or parts. In addition, we provide part nesting options to maximize the part-to-sheet yield and minimize material waste ultimately decreasing part cost. Freedom Fabricators machines a wide variety of materials such as: stainless steel, mild steel, aluminum, brass, copper, carbide, granite, stone, marble, tile, glass, plastics, Lexan/polycarbonate, polypropylene, starboard, rubber, foam, wood, and more!